Industrial Mixers

PerMix News & Updates

The Rise of fresh pet food has been a significant trend in recent years. Pet owners are becoming more conscious about the quality of food they feed their furry friends, and as a result, there has been a surge in the demand for fresh and nutritious meals for pets.

One of the key factors contributing to the rise of fresh pet food is the use of high-quality ingredients. Unlike traditional commercial pet food, which often contains fillers and artificial additives, fresh pet food is made with real, wholesome ingredients that provide optimal nutrition for pets.

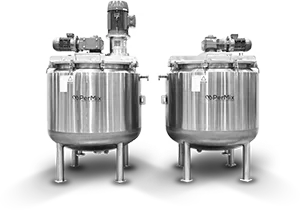

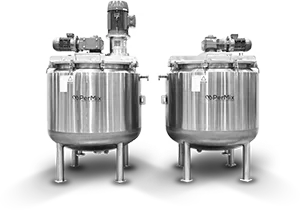

Pets are like family members to many people, and just like humans, they deserve to have a healthy diet. The types of mixers used in the production of fresh pet food play a crucial role in ensuring that the ingredients are properly blended and combined to create a balanced meal.

Mixers are essential in the manufacturing process of fresh pet food as they help in evenly distributing the ingredients, ensuring that each bite contains a nutritious blend. There are various types of mixers used in the pet food industry, each with its own unique features and benefits.

One popular type of mixer used in the production of fresh pet food is the paddle mixer. This type of mixer is designed to gently mix the ingredients without damaging or compromising their nutritional value. Paddle mixers are ideal for blending softer ingredients such as meat, vegetables, and grains.

Another commonly used mixer is the ribbon mixer, which is known for its ability to thoroughly mix dry ingredients. This type of mixer is often used in the production of dry pet food, where precise blending of different grains, vitamins, and minerals is essential.

Of course the sigma mixer is very useful in this area also, especially in areas where extruding the finished product is needed. The extruders of the sigma mixer are different than that used in dry foods. The extruders here are screws or augers that transport the finished product under low pressure and while heating and cooling can be achieved, the nutritional values as well as the texture stays intact as it is not a pressure type and is a single zone.

In addition to paddle and ribbon mixers, there are also tumble mixers, which are used to blend larger batches of fresh pet food. These mixers are designed to handle large volumes of ingredients and ensure that they are evenly distributed throughout the mixture.

Creating a well-balanced and nutritious meal for pets involves not only choosing the right ingredients but also using the appropriate mixers to ensure that the final product meets the highest standards of quality.

In conclusion, the rise of fresh pet food has revolutionized the way pet owners feed their furry companions. With a focus on high-quality ingredients and the use of specialized mixers, pet food manufacturers are now able to provide wholesome and nutritious meals that promote the overall health and well-being of pets. So, if you’re a pet owner looking to provide the best for your furry friend, consider exploring the world of fresh pet food and the various types of mixers used to make it.