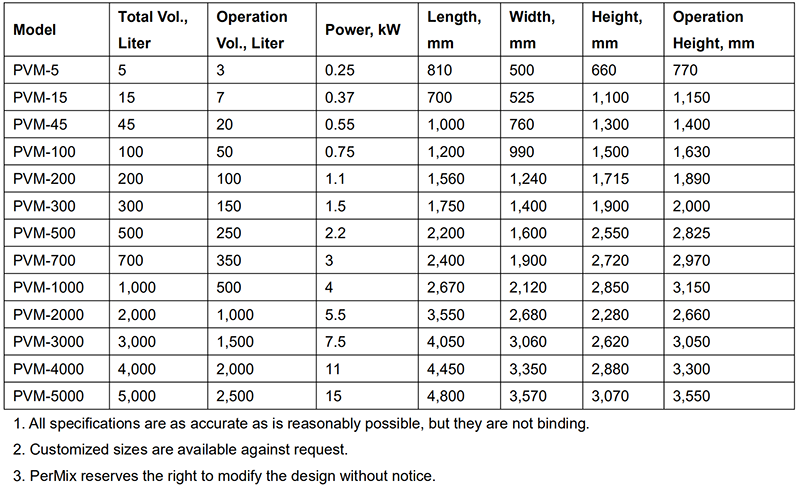

Industrial Mixers

High-Quality PerMix V-Blender, Mixer and Blenders for Efficient Mixing

Best in Innovation • Best In Performance • Best In Quality • Best In Price • Best In Warranty

The PerMix V–Blenders, sometimes also called Y shaped Mixer, is one type of the well-known Tumbler Mixer (the other type is the PerMix PDC series Double Cone Mixer) which is very popular for the intimate blending of free-flowing dry powders, granules, and crystals.

When it comes to V-Blenders and Mixers, PerMix stands as a global leader in innovation, engineering, and performance. With decades of expertise, we manufacture the most efficient and reliable V-Blenders and Mixers designed to meet the diverse needs of industries like pharmaceuticals, food, chemicals, and more. From precision blending of powders to advanced drying capabilities, our mixers outperform the competition in every way.

In addition to our industry-leading V-Blenders, PerMix takes blending to the next level with our C-Blenders and Vacuum Mixers/Dryers. These machines are engineered for versatility and performance, making them the perfect solution for manufacturers seeking multi-functional equipment.

PerMix V-Blenders and Mixers are trusted by top manufacturers in industries such as:

Whether you need a high-performance V-Blender for precision mixing or a versatile C-Blender with vacuum drying capabilities, PerMix has the solution for you.

Contact us today to learn more about our V-Blenders, C-Blenders, and Vacuum Mixers/Dryers, and discover how we can elevate your production processes.

PerMix – Where Engineering Meets Innovation for Superior Mixing Solutions.

Understanding the working principle of V-Blenders and Mixers is key to appreciating why they are the preferred choice for industries like pharmaceuticals, food processing, and chemical manufacturing. These machines are specifically designed to ensure efficient, consistent, and homogenous mixing of dry powders and granular materials, even for complex blends.

The V-Blender gets its name from its distinctive V-shaped cylindrical design. This design is integral to its working principle, as it ensures optimal blending through a gentle tumbling action.

C-Blenders and Vacuum Mixers/Dryers take blending technology further by incorporating advanced features such as vacuum and thermal control, making them highly versatile.

The working principles of V-Blenders and C-Blenders are engineered to:

At PerMix, we design our V-Blenders and mixers with precision engineering to optimize the working principle and meet your unique requirements. With our innovative features and versatile designs, we deliver industry-leading performance, reliability, and value.

Contact us today to learn more about how PerMix V-Blenders, C-Blenders, and Vacuum Mixers/Dryers can transform your production processes!

PerMix takes blending and drying to the next level with a range of customizable options tailored to meet the diverse needs of industries like pharmaceuticals, food, chemicals, and more. From heating and cooling jackets to vacuum systems, our mixers are designed for maximum versatility and efficiency. Below, we explore the available options, including features for explosion-proof (ExP) and ATEX-compliant environments, as well as solutions for abrasive and corrosive materials.

Efficient loading and unloading are critical to streamline production processes. PerMix offers a variety of solutions:

PerMix understands that different industries require different materials to meet their unique challenges:

The Importance Of Intensifier Bars In V-Blenders

In this blog, we will explore the significance of intensifier bars in V blenders. V blenders are widely used in various industries for mixing and blending powders and granules. These versatile machines have a unique design that allows for efficient and uniform mixing. However, the addition of intensifier bars takes the blending process to a whole new level.

Intensifier bars, also known as intensifier arms or baffles, are crucial components in V blenders. They are strategically positioned inside the blender’s mixing chamber to enhance the blending efficiency. These bars play a vital role in breaking up agglomerates, promoting better particle dispersion, and ensuring a homogeneous mix.

One of the key advantages of intensifier bars is their ability to prevent powder segregation. When blending different powders with varying particle sizes and densities, there is a tendency for the heavier particles to settle at the bottom, while the lighter ones remain on top. This can result in an uneven mix and affect the quality of the final product. However, with the presence of intensifier bars, the blending action is intensified, preventing the separation of particles and ensuring a consistent blend.

Another significant benefit of intensifier bars is their role in reducing blending times. By incorporating these bars into the V blender, the mixing action is intensified, resulting in faster and more efficient blending. The bars create additional turbulence and agitation, breaking down any clumps or lumps and facilitating the uniform distribution of particles throughout the mixture.

Furthermore, intensifier bars contribute to improved product quality and consistency. With their help, the blending process becomes more thorough and uniform, minimizing the risk of ingredient stratification or inadequate mixing. This is particularly crucial in industries where product quality and consistency are of utmost importance, such as pharmaceuticals, food processing, and chemical manufacturing.

It is important to note that the design and configuration of intensifier bars may vary depending on the specific V blender model and application. Some V blenders may have multiple intensifier bars, while others may feature adjustable or removable bars to accommodate different blending requirements.

In conclusion, intensifier bars play a crucial role in enhancing the performance and efficiency of V blenders. Their ability to prevent powder segregation, reduce blending times, and improve product quality makes them indispensable in various industries. Whether you are involved in pharmaceuticals, food processing, or any other industry that requires precise and consistent blending, considering a V blender with intensifier bars is a wise choice.

So, next time you are in need of efficient powder blending, don’t forget the importance of intensifier bars in V blenders!

PerMix is here to listen to your needs and provide sustainable solutions. Contact us to discover more.