Industrial Mixers

High-Quality Plow Mixers - Discover the Best Plow Mixer for Your Product Needs

Best in Innovation • Best In Performance • Best In Quality • Best In Price • Best In Warranty

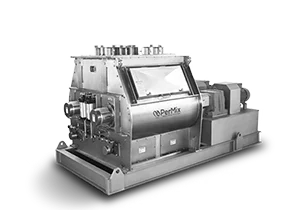

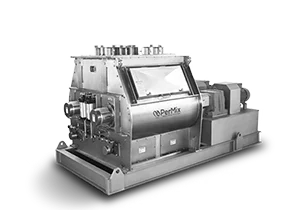

PerMix Plow Mixers lead the industry in technology, performance, and value. PerMix Plow Mixers are available in two types, Horizontal Plow Mixers and Horizontal Plow Mixer / Dryers. Both our Plow Mixers as well as our Plow Mixer / Dryers are available in capacities from 1 liter to 30,000 liters, and have options that are endless

At PerMix, we design and manufacture the most advanced Plow Mixers on the market. Our mixers are engineered to deliver consistent, high-performance results for a wide variety of industries, from pharmaceuticals and food production to chemicals and more. With a range of construction options tailored to meet diverse operational needs, PerMix Plow Mixers are built to exceed expectations.

PerMix Plow Mixers are available in multiple construction types, ensuring optimal performance, durability, and safety for every application:

PerMix extends the functionality of traditional Plow Mixers with advanced vacuum and thermal capabilities. Our Vacuum Plow Mixers/Dryers are engineered to mix, dry, and process materials with unmatched efficiency.

Our Plow Mixers and Vacuum Plow Mixers/Dryers are designed to meet the unique demands of various industries:

Let PerMix help you optimize your mixing processes with our industry-leading Plow Mixers and Vacuum Plow Mixers/Dryers. Contact us now to learn more about our diverse construction options, or to request a custom quote tailored to your needs.

A Plow Mixer, also known as a Ploughshare Mixer, is a high-performance mixing machine designed to blend powders, granules, and even liquids into a homogeneous mixture. Its unique design and operational efficiency make it ideal for industries such as pharmaceuticals, food, chemicals, nutraceuticals, and more.

PerMix is the industry leader in Plow Mixer technology, offering unmatched engineering, innovation, and reliability. Our mixers are designed with flexibility and performance in mind, ensuring they meet the demands of your specific application. With customizable features and materials of construction, including stainless steel, Hastelloy, and Hardox, PerMix plow mixers are the ultimate solution for your mixing needs.

Understanding how a Plow Mixer works is the first step to optimizing your production processes. Contact PerMix today to learn more about our Plow Mixers and how they can elevate your mixing operations.

PerMix Plow Mixers consist of one electrical motor, one gearbox, and a shaft with plows located in a O-shaped vessel.

The plows are designed in such a way that the powder materials are guided to move from the two ends of the vessel to the center, and meanwhile from center to both ends and side to side, and over, until the batch is mixed thoroughly.

In addition Plow Mixers also lift the ingredients into the air, mixing them in a “fluidized zone” then allow them to drop back down. In such a three-dimensional way, the total powder can be mixed fast in the vessel. It asks for a short mixing time and relatively low power consumption.

PerMix’s Vacuum Plow Mixers/Dryers combine superior mixing technology with advanced drying capabilities, making them the ideal solution for a wide range of industries, including pharmaceuticals, food, chemicals, nutraceuticals, and more. Designed for efficiency and versatility, these mixers handle even the most complex processes with ease, ensuring uniform mixing and fast drying in a single, compact unit.

A Vacuum Plow Mixer/Dryer is a high-performance machine that integrates the robust mixing action of a Plow Mixer with the benefits of vacuum technology. These mixers are equipped with a vacuum system and heating or cooling jackets, allowing them to dry products while mixing under reduced pressure. This unique design ensures rapid moisture removal, low-temperature drying, and high-quality end results.

PerMix has a global reputation for delivering the most reliable and efficient Vacuum Plow Mixers/Dryers on the market. Our mixers are designed with advanced engineering, unmatched quality, and a focus on affordability. Whether you need a sanitary solution for pharmaceuticals, a durable design for abrasive products, or an explosion-proof mixer for hazardous materials, PerMix has you covered.

Discover how PerMix Vacuum Plow Mixers/Dryers can optimize your mixing and drying processes. Contact us today to learn more about our innovative solutions or request a custom quote for your specific needs. Let PerMix take your production to the next level.

The PerMix Hybrid Plow Mixer / Dryers have the same mixing principle as our Horizontal Plow Mixers & Plow Mixer / Dryers but add the ability for the operator to change agitation type with ease, switching from paddle to plow, or even segmented ribbon.

Plow Mixer Powder Mixing Configurations:

Food flavoring/additives, Sponge/cake mixes, Cosmetics, Pharmaceuticals, Cement, Powdered rubber.

Plow Mixer Paste Mixing Configurations:

Biscuit creams, dough, PVC pastes, Car body fillers/putties, Sugar/marzipan paste, Toiletry pastes, Tile adhesives, and grouts.

Plow Mixer Mixing Of Wet Slurries:

Filter cake re-slurrying, dough, Fiberglass resin dough putty.

Wet granulation, Liquid coating of powders and granules, Fat and oil incorporation, Vacuum drying, Hot air drying.

PerMix is renowned for its cutting-edge Plow Mixers, offering unmatched performance, reliability, and versatility across industries such as pharmaceuticals, food, chemicals, nutraceuticals, and more. With innovative engineering and robust design, PerMix Plow Mixers deliver superior results for even the most challenging mixing applications.

PerMix Plow Mixers are designed with plow-shaped blades that create a fluidized mixing zone. This ensures fast, uniform blending of powders, granules, and liquids. The unique three-dimensional mixing action eliminates dead spots, providing consistent results in minimal time.

PerMix Plow Mixers excel in handling diverse mixing tasks:

From pharmaceuticals and food to construction materials, these mixers adapt to virtually any process.

Every production process is unique, and PerMix Plow Mixers can be customized with options like:

PerMix Plow Mixers are built to last, with materials suited to your specific needs:

PerMix Plow Mixers are available in sizes ranging from lab-scale models for R&D to large-scale industrial units for full production. This scalability allows seamless growth as your production needs expand.

Engineered for optimized performance, PerMix Plow Mixers reduce energy consumption while delivering consistent results. The design minimizes downtime, ensuring higher throughput and lower operational costs.

For industries like pharmaceuticals and food, PerMix Plow Mixers feature sanitary designs that meet FDA and cGMP standards. Polished interiors, easy-clean designs, and optional Clean-In-Place (CIP) systems make them ideal for stringent hygiene requirements.

PerMix mixers are built with durability in mind. High-quality components and robust materials ensure minimal maintenance and a long service life, maximizing your return on investment.

With decades of experience and a strong global presence, PerMix is trusted by manufacturers worldwide for delivering reliable, high-quality mixing solutions.

PerMix Plow Mixers outperform competitors with their innovative design, superior performance, and customizable options. Whether you’re blending powders, introducing liquids, or processing abrasive materials, a PerMix Plow Mixer is the ultimate solution for efficient, reliable mixing.

Choose from a variety of materials to match your application:

PerMix Plow Mixers: Engineering Excellence in Performance

PerMix takes pride in designing and manufacturing the industry’s most advanced Plow Mixers. The performance of a Plow Mixer is heavily influenced by the precise design of the plow, particularly the pitch and the trailing edge. These critical design elements directly affect the efficiency, uniformity, and speed of the mixing process.

The pitch of the plows determines the movement and trajectory of the materials within the mixer. A well-designed pitch creates a dynamic mixing action that ensures:

The trailing edge of the plow, often overlooked, is just as critical as the pitch. This feature contributes to:

The performance of a Plow Mixer depends on more than just the power of its motor or the size of its chamber; the true differentiator lies in the design of the plow. PerMix Plow Mixers stand out because:

PerMix’s engineering excellence is evident in every detail of our plow mixers. Our expertise in plow design ensures unparalleled mixing performance, whether you’re blending powders, pastes, or adding liquids to dry materials.

When it comes to Plow Mixers, the design of the plow is not just a feature—it’s the key to performance, and PerMix continues to lead the way in innovation and quality.

PerMix is here to listen to your needs and provide sustainable solutions. Contact us to discover more.