Industrial Mixers

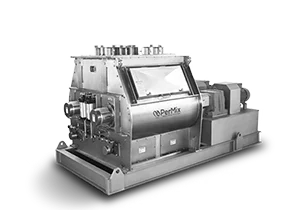

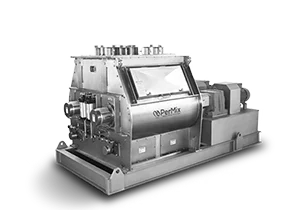

PerMix Paddle Mixer

Best in Innovation • Best In Performance • Best In Quality • Best In Price • Best In Warranty

PerMix Paddle Mixers lead the industry in technology, performance, and value.

PerMix Paddle Mixers are available in four types, our standard Horizontal Paddle Mixers, Horizontal Paddle Mixer / Dryers, Twin Shaft Paddle Mixers, also called Fluidized Zone Mixers & our new Vertical Paddle Mixers called our PAM Series.

When it comes to Paddle Mixers, PerMix sets the standard for excellence. Our mixers are engineered with precision, designed to deliver consistent and efficient performance across various industries. With decades of expertise, innovation, and customer trust, we proudly manufacture the best Paddle Mixers on the market. Whether you’re mixing powders, granules, or incorporating liquids into your process, PerMix Paddle Mixers are the perfect solution for your needs.

Paddle Mixers are horizontal mixers equipped with paddles mounted on a shaft. These paddles create a unique mixing action that lifts, folds, and gently tumbles materials, ensuring a homogeneous mix. They are particularly effective for:

Our Paddle Mixers are versatile and cater to a variety of industries, including:

PerMix takes Paddle Mixers to the next level by incorporating vacuum capabilities and heating & cooling jackets. These features transform traditional Paddle Mixers into Vacuum Paddle Mixers/Dryers, providing unparalleled versatility in production processes.

When you choose PerMix, you’re choosing unmatched quality and value. Here’s why we stand out:

Whether you need a standard Paddle Mixer or a customized Vacuum Paddle Mixer/Dryer, PerMix is your trusted partner. With our innovative designs and superior performance, we guarantee to meet and exceed your expectations.

Contact us today to learn more about how our Paddle Mixers can transform your production process and help you stay ahead of the competition!

A Paddle Mixer is a versatile industrial mixing solution widely used across industries for its efficient blending capabilities. Its unique design and working principles make it ideal for mixing a variety of materials, including powders, granules, liquids, and combinations of these. Here’s an in-depth look at how Paddle Mixers work and why they are a preferred choice for many applications.

The operation of a Paddle Mixer is based on a simple yet effective mixing mechanism. It uses paddles mounted on a central shaft inside a horizontal or vertical cylindrical mixing chamber. These paddles are strategically designed and positioned to move materials in a specific pattern, ensuring thorough and uniform mixing.

Thanks to their versatile working principles, Paddle Mixers are used in industries such as:

The efficiency and flexibility of Paddle Mixers stem from their robust design and unique mixing principles. They:

At PerMix, we take Paddle Mixers to the next level. Our mixers are designed with innovation, precision, and performance in mind. With advanced features like vacuum functionality, heating and cooling jackets, and explosion-proof construction, PerMix Paddle Mixers provide unmatched versatility for any industry.

Contact us today to learn more about the working principles of Paddle Mixers and discover how PerMix can optimize your production process.

PerMix Paddle Mixers are renowned for their versatility, performance, and ability to meet the unique needs of industries worldwide. Our mixers are more than just machines—they’re precision-engineered solutions designed for durability, efficiency, and adaptability. Whether your process demands sanitary construction for pharmaceuticals, explosion-proof designs for hazardous environments, or materials built to handle abrasive and corrosive products, PerMix delivers.

At PerMix, we understand that no two applications are alike. That’s why we offer a range of construction options to ensure our Paddle Mixers meet the specific demands of your industry:

In addition to tailored construction, PerMix Paddle Mixers offer a range of cutting-edge features:

PerMix Paddle Mixers cater to a wide variety of applications:

PerMix doesn’t just make mixers—we create solutions that elevate your production. Whether you need a Sanitary Paddle Mixer for pharmaceuticals, a heavy-duty mixer for abrasive materials, or an explosion-proof mixer for hazardous environments, PerMix is the trusted choice.

Vacuum mixer/dryers are innovative machines that combine the processes of mixing and drying into a single, efficient operation. Designed for industries requiring precise control over moisture content, temperature, and material handling, these versatile systems offer unparalleled efficiency and product quality.

In this guide, we’ll explore the working principles of vacuum mixer/dryers, the industries that rely on them, and their diverse applications.

The operation of a vacuum mixer/dryer is based on a combination of mixing, heating (or cooling), and drying under reduced pressure. This multi-functional approach ensures uniform results while preserving material integrity.

Vacuum mixer/dryers are used across a wide range of industries, each benefiting from their precise drying capabilities, efficient mixing, and ability to handle delicate or sensitive materials.

Vacuum Mixer/Dryers offer unique advantages that make them a must-have for industries requiring efficient, high-quality production:

At PerMix, we design Vacuum Mixer/Dryers tailored to your specific needs. From pharmaceutical-grade construction to explosion-proof designs for hazardous environments, we deliver solutions that excel in quality, efficiency, and performance.

Whether you’re producing life-saving pharmaceuticals, flavorful food products, or high-performance chemicals, PerMix Vacuum Mixer/Dryers provide the precision and efficiency you need. Contact us today to learn how our advanced systems can transform your production process.

The PerMix Hybrid Paddle Mixer / Dryers have the same mixing principle as our Horizontal PaddleMixers & PaddleMixer / Dryers but add the ability for the operator to change agitation type with ease, switching from paddle to plow, or even segmented ribbon.

Our Twin Shaft Paddle Mixers / Fluidized Zone Mixers are ideal for mixing ingredients of different density & particle size as the twin paddle design “flings” the ingredients in the air with such velocity the mixingis done in the air, in a gravity-free zone where density & size do not matter.

The PerMix Vertical Paddle Mixer is a cutting-edge solution for efficient mixing across industries. Designed with a vertical cylindrical vessel and precisely angled paddles, it delivers uniform blending, superior performance, and seamless integration into your production process. For advanced applications, our Vertical Vacuum Paddle Mixer/Dryer combines mixing and drying in a single unit, offering unmatched versatility and efficiency.

A Vertical Paddle Mixer uses a vertical mixing chamber with centrally mounted paddles that rotate to lift, fold, and mix materials. This unique design ensures homogeneous blending of powders, granules, and liquids while minimizing floor space requirements.

The Vertical Vacuum Paddle Mixer/Dryer takes the functionality of a standard vertical mixer and enhances it with vacuum and thermal capabilities. This advanced system is perfect for industries requiring efficient drying, moisture removal, and solvent recovery.

PerMix Vertical Paddle Mixers and Vacuum Paddle Mixer/Dryers are designed to meet the needs of diverse industries:

PerMix Vertical Paddle Mixers prioritize hygiene and operational efficiency with advanced cleaning options:

PerMix is the global leader in designing and manufacturing innovative mixing and drying solutions. Our Vertical Paddle Mixers and Vacuum Paddle Mixer/Dryers deliver:

Whether you need a compact mixer for space-saving operations or a versatile vacuum mixer/dryer for advanced applications, PerMix Vertical Paddle Mixers are the ultimate solution. With superior engineering, customizable features, and industry-specific designs, PerMix helps you achieve efficient, high-quality production.

Paddle Mixer Powder Mixing Configurations:

Food flavoring/additives, Sponge/cake mixes, Cosmetics, Pharmaceuticals, Cement, Powdered rubber.

Paddle Mixer Paste Mixing Configurations:

Biscuit creams, dough, PVC pastes, Car body fillers/putties, Sugar/marzipan paste, Toiletry pastes, Tile adhesives and grouts.

Paddle Mixer Mixing Of Wet Slurries:

Filter cake re-slurrying, dough, Fiberglass resin dough putty. Wet granulation, liquid coating of powders and granules, fat and oil incorporation, vacuum drying, hot air drying.

For the latest info on customers, applications, & global installations, visit our blog or visit us on LinkedIn PerMix Paddle Mixer Options.

At PerMix, we understand that every industry has unique requirements for their mixing processes. That’s why our mixers are designed with a range of customizable options to meet the specific demands of your application. Whether you’re working with hazardous materials, abrasive and corrosive ingredients, or need advanced cleaning and loading solutions, PerMix mixers are built to exceed expectations.

Industries dealing with flammable, reactive, or volatile materials require specialized equipment to ensure safety. PerMix offers mixers with ExP (Explosion-Proof) and ATEX-certified designs for safe operation in hazardous zones.

Mixing abrasive or corrosive materials requires equipment that can withstand extreme conditions without compromising performance. PerMix offers a variety of construction materials and designs tailored for durability and longevity.

Efficient material handling is critical for maximizing productivity. PerMix mixers offer multiple loading and unloading solutions to streamline your process.

Adding liquids during the mixing process is essential for many applications. PerMix mixers are equipped with features that ensure even liquid distribution.

Maintaining hygiene and cleanliness is critical, especially in industries like food, pharmaceuticals, and chemicals. PerMix offers advanced cleaning-in-place (CIP) systems for effortless maintenance.

At PerMix, we combine innovation, engineering, and quality to deliver mixers that meet and exceed industry standards. From hazardous environments to delicate food production, our mixers are built for efficiency, safety, and longevity.

Looking for a mixer with explosion-proof capabilities, corrosion-resistant materials, or streamlined cleaning options? PerMix has you covered. Contact us today to learn how our customizable mixers can elevate your production process.

When it comes to Paddle Mixers, PerMix stands out as the leader in the industry. Designed with precision engineering, innovative features, and superior construction materials, our Paddle Mixers deliver exceptional performance across a wide range of applications. From gentle mixing to heavy-duty processing, PerMix Paddle Mixers offer a level of versatility and efficiency that sets them apart from the competition.

Here’s why PerMix paddle mixers are the ultimate solution for your mixing needs.

PerMix Paddle Mixers are designed for optimal performance, ensuring thorough and consistent blending of materials.

No matter your industry, PerMix Paddle Mixers deliver exceptional results for a variety of processes.

PerMix Paddle Mixers are tailored to meet the unique requirements of your application.

PerMix Paddle Mixers are designed to streamline your workflow with flexible loading and unloading options.

PerMix Paddle Mixers prioritize hygiene and operational efficiency with advanced cleaning options.

PerMix mixers are built to last, even in the most demanding environments.

PerMix Paddle Mixers are designed to maximize efficiency while minimizing operational costs.

PerMix offers more than just high-performance Paddle Mixers. We deliver:

From robust construction to innovative features, PerMix Paddle Mixers are designed to outperform and outlast the competition. Whether you need a mixer for food production, pharmaceuticals, or industrial processes, PerMix is your trusted partner for quality and efficiency.

PerMix is here to listen to your needs and provide sustainable solutions. Contact us to discover more.