Industrial Mixers

PerMix News & Updates

Mixing powdered metals for 3D printing is a crucial process that plays a significant role in the manufacturing industry and PerMix is a leader in this area. By combining different metal powders & binders, engineers and designers can create unique alloys with enhanced properties, making them suitable for various applications. In this article, we will delve into the intricate process of mixing powdered metals for 3D printing and explore its benefits and challenges.

The Importance of Mixing Powdered Metals

When it comes to 3D printing with metals, the ability to mix different powdered metals & binders opens up a world of possibilities. By blending metal powders together, manufacturers can achieve desired mechanical, thermal, and chemical properties that cannot be obtained using a single metal alone. This flexibility allows for the creation of tailored materials with enhanced strength, durability, and even magnetic or conductive properties.

The Process of Mixing Powdered Metals

Mixing powdered metals for 3D printing involves precise measurements, careful selection of metal powders, and thorough mixing techniques. The first step is to identify the desired properties of the final alloy and select the appropriate metal powders & binders accordingly. These powders are often sourced from reputable suppliers and undergo strict quality control to ensure their purity and consistency.

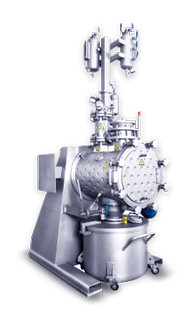

Once the metal powders are obtained, they are carefully weighed and mixed in specific ratios to achieve the desired alloy composition. This can be done through various methods, such as mechanical mixing, ball milling, or even using specialized equipment like powder blending machines. The goal is to ensure a homogeneous mixture with uniform distribution of the different metal powders.

The Benefits and Challenges

Mixing powdered metals for 3D printing offers numerous benefits. Firstly, it allows for the creation of custom alloys with tailored properties, meeting specific requirements for different applications. This opens up opportunities for innovation and advancement in industries such as aerospace, automotive, and medical.

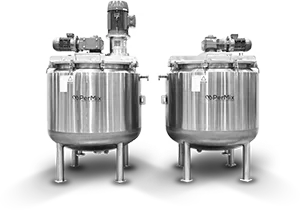

However, the process of mixing powdered metals also presents its fair share of challenges. Achieving a precise and consistent alloy composition can be complex, as slight variations in mixing ratios can significantly impact the final properties of the material. Additionally, certain metal combinations may exhibit different levels of compatibility, requiring additional experimentation and optimization. PerMix offers several solutions for mixing, as well as loading & unloading.

Conclusion

In conclusion, mixing powdered metals for 3D printing is a vital process that enables the creation of unique alloys with enhanced properties. By carefully selecting and blending different metal powders, engineers and designers can unlock a world of possibilities, pushing the boundaries of what is achievable in metal additive manufacturing. As technology continues to advance, the ability to mix powdered metals for 3D printing will undoubtedly play a pivotal role in shaping the future of manufacturing.

Come see the PerMix difference and contact us for more information