Industrial Mixers

PerMix News & Updates

Mixing Complications Experienced When Mixing in Zinc Oxides to Cremes

When it comes to formulating skincare products, incorporating zinc oxides into cremes can present certain challenges. In this blog post, we will explore the various complications that may arise during the mixing process and discuss potential solutions. So, let’s dive in!

One of the common issues encountered when mixing zinc oxides into cremes is inadequate dispersion. This occurs when the particles of zinc oxide do not evenly distribute throughout the creme, leading to inconsistent product performance. To address this problem, it is essential to take the following steps:

Zinc oxides can impart a white color to cremes due to their inherent characteristics. However, achieving consistent color throughout the product can be challenging. Here are some strategies to minimize color variation:

Another challenge when working with zinc oxides in cremes is the potential stability issues they can introduce. These can manifest as changes in texture, odor, or even degradation of active ingredients. Here are a few tips to enhance stability:

In conclusion, incorporating zinc oxides into cremes can pose some challenges during the mixing process. However, by following proper techniques, such as adequate dispersion, addressing color variation, and enhancing stability, these complications can be effectively managed. Remember to always test and evaluate your formulations to ensure the desired results. Happy formulating!

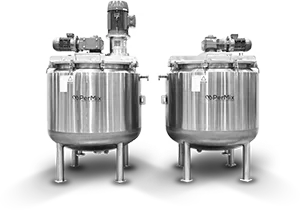

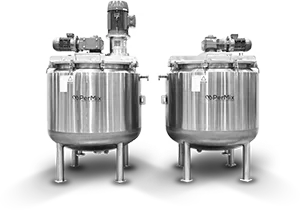

Come see the Permix difference!