Industrial Mixers

PerMix News & Updates

Granulating Honey

Granulating honey is a process that involves the transformation of liquid honey into a granulated form. This method has gained popularity among honey producers and consumers alike due to its numerous benefits. In this article, we will explore the use of high-speed granulators for granulating honey, their advantages, and the step-by-step process involved.

Why Granulate Honey?

Granulated honey offers several advantages over its liquid counterpart. Firstly, it has a longer shelf life, making it easier to store and transport. Additionally, granulated honey is less messy and more convenient to use, as it can be easily scooped or measured. Furthermore, granulated honey tends to have a smoother texture and is preferred by many for spreading on toast or mixing into beverages.

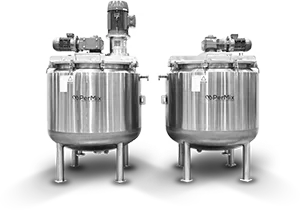

The Role of High-Speed Granulators

High-speed granulators play a crucial role in the granulation process. These machines are specifically designed to break down the structure of liquid honey into smaller granules. The high-speed rotation of the granulators helps to remove excess moisture and create the desired granulated texture. The use of high-speed granulators ensures consistent and uniform granulation, resulting in a high-quality product.

The Granulating Process

Now, let’s delve into the step-by-step process of granulating honey using high-speed granulators.

1. Preparation: Start by gathering all the necessary equipment, including the high-speed granulator, honey, and granulation trays. Ensure that the granulator is clean and properly sanitized before use.

2. Temperature Control: It is crucial to maintain the appropriate temperature during the granulation process. Honey is typically heated to around 50-60 degrees Celsius to reduce its viscosity and facilitate granulation.

3. Pouring the Honey: Carefully pour the liquid honey into the high-speed granulator. The machine will then start its rapid rotation, breaking down the honey into smaller granules.

4. Granule Size Adjustment: Depending on the desired granule size, you may need to adjust the settings of the high-speed granulator. This will allow you to achieve the desired texture and consistency of the granulated honey.

5. Drying Stage: After the granulation process, the honey granules will still contain some moisture. Reduce agitation speed and reduce vacuum (if using) and allow it to dry for a specific period. This step ensures that the excess moisture is evaporated, resulting in a stable and dry granulated honey product.

6. Packaging: Once the granulated honey has fully dried, it is ready for packaging. Use airtight containers or jars to maintain its freshness and prevent moisture absorption.

Conclusion

Granulating honey using high-speed granulators is a highly effective method for transforming liquid honey into a granulated form. The use of these machines ensures consistent granulation, resulting in a high-quality product with a longer shelf life. Whether for personal use or commercial production, granulated honey offers convenience and versatility. So next time you reach for a jar of honey, consider the benefits of granulated honey and enjoy its smooth texture and ease of use. Come see the PerMix difference