Industrial Mixers

PerMix News & Updates

Unlock Effortless Glass Fiber & Resin Mixing with PerMix Sigma Mixer – Get Stronger Results Faster!

Mixing glass fibers with resin is essential for producing high-strength composites, but traditional mixing methods often fall short, causing frustrating inefficiencies that affect your production quality and speed.

❌ Inconsistent Dispersion – Poor mixing results in weak composite structures with uneven fiber distribution.

❌ Fiber Breakage – Harsh mixing techniques damage the structural integrity of fibers, reducing final product performance.

❌ Handling High-Viscosity Resins – Thick, dense resins can clog mixing equipment, causing delays and inconsistent results.

❌ Air Pockets & Imperfections – Trapped air leads to defects in composites, weakening materials and requiring costly rework.

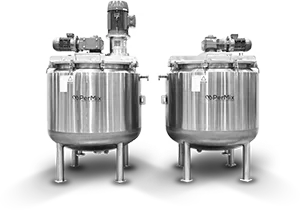

At PerMix, we redefine the mixing process to eliminate these inefficiencies. Our Sigma Mixer is engineered for precision, power, and speed, delivering high-performance mixing while preserving fiber integrity.

✅ Perfect Fiber Dispersion – Our dual Z-blades ensure flawless mixing, preventing fiber breakage and achieving uniform dispersion for stronger, more durable composites.

✅ Reduce Waste & Downtime – Advanced vacuum and temperature controls eliminate air pockets and regulate resin viscosity, ensuring defect-free, high-quality production.

✅ Effortless High-Viscosity Mixing – Handle even the thickest resins with ease, ensuring a smooth, consistent, and efficient production process.

✅ Boost Efficiency Without Compromising Quality – No need to choose between powerful mixing and fiber protection—PerMix delivers both for superior composite materials.

✅ Custom Discharge Options – Choose from tilt, bottom valve, or extrusion screw discharge to match your production needs and optimize workflow.

✅ Sanitary & Easy to Clean – Our CIP-ready (Clean-in-Place) system ensures fast, hygienic cleaning between batches, minimizing downtime and contamination risks.

PerMix solutions are trusted by manufacturers in diverse industries, including:

🚀 Aerospace & Aviation – High-strength, lightweight composites for aircraft components

🚗 Automotive & Transportation – Durable fiber-reinforced materials for cars, trucks, and trains

🛥️ Marine & Shipbuilding – Corrosion-resistant, reinforced fiberglass composites

🏗 Construction & Infrastructure – Strong, weather-resistant composite building materials

🔬 Advanced Manufacturing – Specialized engineered composites for high-performance applications

✔ Stronger, higher-quality composite materials

✔ Reduced waste, defects, and production downtime

✔ Optimized mixing process for faster, more consistent results

✔ Greater efficiency and cost savings in production

Don’t settle for inefficient mixing solutions that slow down your production. Upgrade to the PerMix Sigma Mixer and experience stronger composites, faster production, and better results.

📞 Contact us today to learn how PerMix can optimize your manufacturing process and give you a competitive edge!

🔗 For additional insights on our PSG Mixer, click here.